Winter can present several challenges for boilers as temperatures drop and people begin to use their central heating system again after months of inactivity. To help customers save on fuel bills and reduce the risk of unexpected faults or breakdowns during the colder months, here are five simple steps to ensure your Keston boiler continues to perform efficiently all year round.

1. Test run the central heating system.

Many people make the mistake of completely turning off their central heating system during the warmer months and then turning it back on only when the cold weather arrives. By this time, identifying any faults can lead to an uncomfortable and chilly wait. The good news is that running a quick boiler check can help identify most problems before the cold weather sets in. To start, run the boiler and radiators at the highest temperature for around 15 minutes to ensure everything is working properly.

2. Visually inspect the boiler.

Next, inspect the boiler for any visible signs of damage, leaks, and unusual wear. Be sure to check the area beneath and around the boiler, as well as the pipework, for any water drips, rust, corrosion, or loose connections. Other signs that indicate the boiler might need attention include black stains on and around the appliance, a pilot light that frequently goes out, a flame colour other than blue, or a longer-than-usual time for the system to heat up.

3. Bleed radiators.

As part of your checks, it's also important to look at any radiators inside of the property. This is especially relevant in buildings with older heating systems or systems that may not have been used for a while, as trapped air may have accumulated. This can subsequently affect the amount of heat distributed. To bleed radiators, simply use a radiator key to open the bleed valve. Once open, you should hear a hissing sound. This will indicate that any excess air is escaping.

However, it’s important to remember that if you don’t hear the release of air or water this could be due to inadequate boiler pressure. To check boiler pressure, look for a pressure gauge, or something similar, on the boiler to help validate this.

4. Check boiler pressure.

Low boiler pressure is typically caused by a reduction in the amount of water in the system, which can be a common issue thanks to small leaks on joints in the heating system particularly around radiator valves, evacuation of any residual air in the system by auto-air vents, or a pressure relief valve that is passing. Keston boilers feature an easy-to-see pressure gauge, so check to see if the boiler has lost pressure. Typical boiler pressure is around one to 1.0 - 1.5 bar when the system is cool. For boilers showing 0.5 bar or less, this indicates that the boiler will need to be repressurised, and the boiler itself might display a low water pressure fault. But it’s worth bearing in mind that if the system needs to be repressurised more than a couple of times in a year, this could potentially indicate a more serious leak, which will need attention.

5. Unfreeze frozen condensate pipework.

When it comes to winter, one of the most common problems with modern boilers is frozen condensate on pipework. However, before attempting to unfreeze pipework, it’s important to ensure this is the actual fault. Keston boilers can be checked by the following:

- On Keston Combi and System boilers: you see the error code L2or F2

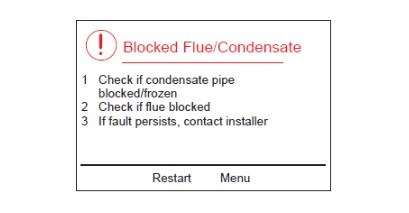

- On Keston Combi 2 and System 2 boilers: you see an error message

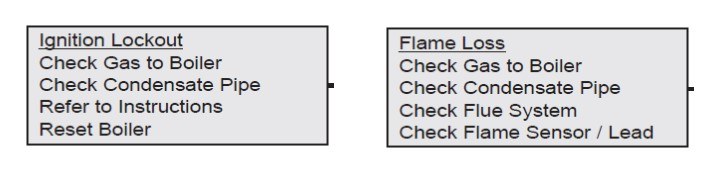

- On Keston Heat boilers: the display could show either an IGNITION LOCKOUT or FLAME LOSS FAULT, and shows Check Condense Pipe

- The boiler makes a gurgling noise

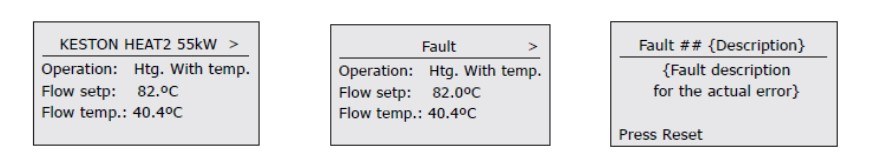

- On Keston Heat 2 boilers: the display could show either ignition lockout or flame loss faults, Fault 52 – 58.

In any of the above situations, the boiler’s condensate pipe may be frozen - but don’t panic, the solution is simple. Start by locating the condensate pipe which runs from the bottom of the boiler. It could be a white or grey plastic pipe that runs through the wall and outside the property for part of its length. Remove any insulation that is fitted to the condensate pipework. From here, simply apply heat around the pipework. You could also pour tepid water over the frozen section of the condensate pipe. To help prevent further freezing, refit the insulation sleeves onto the boiler’s condensate pipe. Once you have cleared the blockage from the condensate pipe press the restart button.

Here at Keston, we want all our customers to feel warm and comfortable, so stay one step ahead of the weather this winter.

For more help with your Keston boiler, please contact the Keston team on 01482 443005 or you may find the answer to your questions by contacting us.