Have you recently visited a property with an old existing twin flue boiler? We've created a quick guide to help you understand what to consider when replacing a twin flue system.

Identify the current boiler

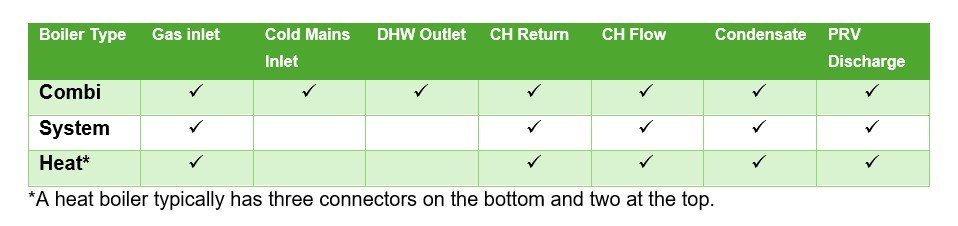

When replacing a twin flue system, the first step is to identify the existing boiler. Start by visually inspecting the data plate. This will typically display the boiler's kW capacity and indicate whether it is a heat only, system, or combi boiler. It will also specify the type of gas used. If the data plate is not visible or has become damaged over time, it's a good idea to search for the Installation Manual, which may provide the necessary information. Additionally, any Annual Gas Safety Inspection or Service Records left by previous engineers will provide details about the appliance. You could also check the number of service connections to help identify the current boiler.

Another way to identify an existing boiler is to examine its flue configuration. To do this, identify the boiler location. If the boiler is mounted on an outside wall, as is common in most domestic settings, it will have a concentric flue that goes directly through that wall. In some cases, especially where the boiler is not on an outside wall, a concentric flue may run vertically off the boiler, through any loft space, and terminate through the roof. On an outside wall a concentric flue can be recognised by its terminal, which features a smaller diameter flue gas pipe arranged concentrically inside the air inlet pipe.

In challenging installations, where the boiler is neither mounted on an outside wall, nor positioned to allow a vertical flue run, and where the distance to reach an outside wall with a horizontal flue exceeds the limits of standard concentric flues, you will find a twin flue arrangement.

Does the boiler need to be moved to an external wall?

While most domestic boilers are usually installed on an external wall, which allows the flue to be easily directed outside, not every installation is that simple.

Fortunately, the Keston twin flue system allows you to run the flue either vertically, or horizontally with a minimum fall of 1.5° back to the boiler. Additionally, the flue can be extended up to 27m* from the boiler for greater flexibility in the boiler position. This avoids the need to relocate the boiler to accommodate a concentric flue and provides a practical and cost-effective solution.

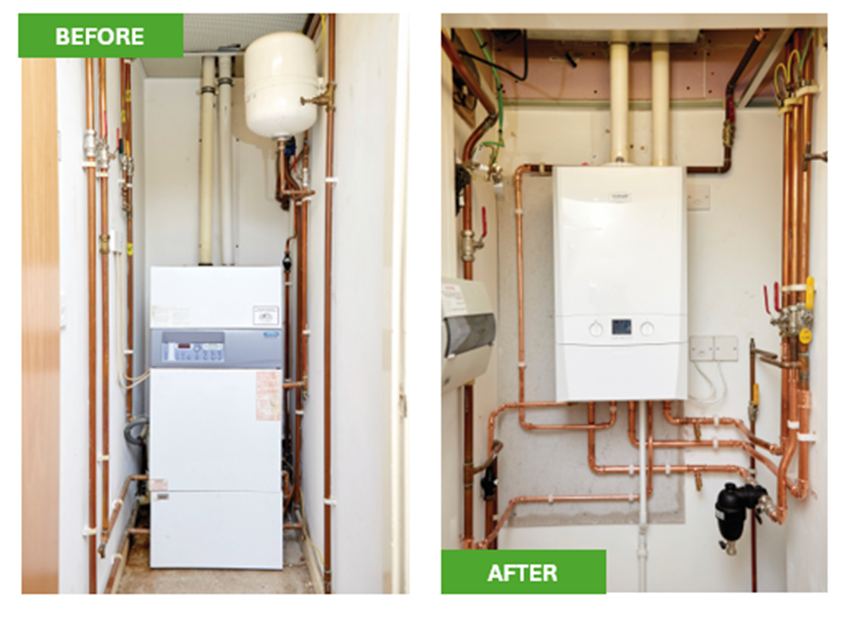

Replacing the current twin flue system

When replacing an existing twin flue boiler, it's essential to replace the old flue system with an approved Keston flue system. This will help ensure the longevity of the new system. Keston boilers have been designed to use Ø50mm muPVC solvent weld pipe systems for both the air and flue runs. This can help to cost-effectively simplify the process. For a list of approved manufacturers and components from each manufacturer's range, for use as flue on Keston boilers, simply refer to the relevant boiler installation manual.

Remember, the size of the air and flue ensures that wherever the old flue was routed, it will be possible to route the new Keston twin flue.

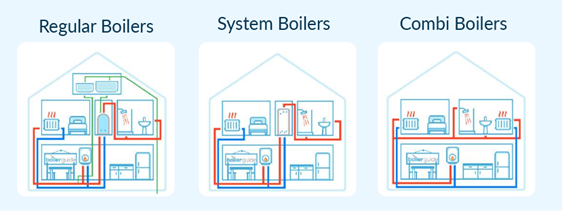

Can You Have a Twin Flue Combi Boiler?

Yes, depending on the circumstances and the unique needs of each property, you may want to install a system, heat only, or a combi twin flue boiler. At Keston we offer all three types of appliances, meaning there’s a central heating solution available for every application.

There’s no one-size-fits-all solution when it comes to boiler installations. The good news is Keston’s twin flue boiler systems make installation jobs simple and provide installers with maximum flexibility. Offering a longer flue run, Keston twin flue boilers remove the need to flue concentrically through the nearest wall or roof. This makes them a perfect choice for installation without compromise.

Speak to a member of our expert team today for more information