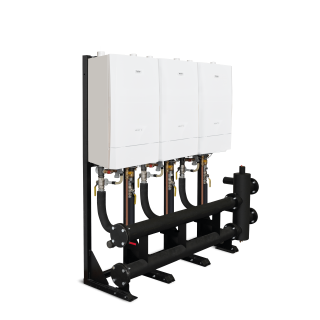

A cascade system (sometimes called a frame and header kit) is a way of harnessing the output of multiple boilers to work together. This means property owners can benefit from a more accurate understanding of demand to provide buildings with optimal levels of central heating and hot water.

Heating commercial buildings and larger commercial premises can be more expensive than it needs to be, especially without an energy-efficient central heating system in place. Although the UK has shifted to only using condensing boilers, this change alone is unlikely to provide the optimal solution for properties.

In this blog we will take a look at how cascade systems work, the energy-efficient benefits they can bring and how they can help boilers last longer.

What is a Boiler Cascade System?

Cascade systems link up multiple boilers, allowing them to work in sync to provide heat and hot water to meet the needs of a building. A cascade system is generally made up of between two and six boilers, with the number of appliances determined by the heat output that’s needed.

Utilise a Reliable Boiler Cascade Kit

Because a cascade system allows multiple boilers to share the load of providing heating and hot water, it means less strain is placed on each appliance. Cascades allow a multi-boiler system to maintain a fixed temperature with less effort, helping them work more efficiently for longer. Together with an annual service, you can rest assured that your boiler system is in good shape.

The boilers are linked together in a way that means they can communicate, allowing them to take it in turns to provide heat and hot water to match demand in the building. When that demand lessens, they will reduce their output accordingly in order to conserve energy and save you money.

An Energy-Efficient Central Heating Solution

Using a cascade system offers several benefits over using one large boiler to try to heat a larger building. A single appliance that’s trying to supply heat to a large area carries the risk of oversizing; this means it would regularly cycle on and off, placing unnecessary stress on the central heating system.

Working that hard is difficult to maintain for a boiler and leads to excessive use of fuel and an increased risk of wear and tear. Because a cascade allows multiple boilers to work together and takes away reliance on a single appliance, it offers greater energy efficiency and makes it far more likely your boilers will last longer.

Flexible and Intelligent Heating

A further benefit of cascade boiler systems allowing communication between appliances is that, if one of the appliances was to break down, the others will recognise the situation and compensate accordingly. Compared to a situation where only one boiler is responsible for the heat and hot water in a building and subsequently breaks down, a cascade system offers a clear and obvious advantage.

Increased Modulation Ratios

The EUA neatly defines boiler modulation as ‘a boiler’s ability to reduce its maximum output to its minimum output, in line with system demand’. A boiler capable of providing a maximum output of 55kW and a minimum output of 11kW is described as having a modulation ratio of 5:1.

The higher the modulation ratio of a boiler, the less need there is for it to regularly cycle on and off, which can mean energy savings and less risk of parts deteriorating from overuse. When boilers are part of a cascade system, the ratio is increased in line with the sum of their maximum outputs.

How Cascade Systems Boost Modulation Ratios

Carrying on from our example above, a cascade system made up of four boilers with a maximum output of 55kW and a minimum output of 11kW would collectively have a maximum output of 220kW and a minimum output of 11kW. This provides a modulation ratio increased fourfold to 20:1, providing a broad range of outputs while also further increasing the benefits outlined above.

Easy to Install

Boiler cascade systems are usually simple to install as they are made up of integrated components from the same manufacturer. Looking at Keston’s Heat 2 Frame and Header Kits as an example, you can install up to six Keston Heat 2 boilers in a simple system installation that allows for outputs from 90kW to 330kW.

When you fit boilers with a twin flue system, it can make tricky installation jobs much simpler, with some models providing flue runs of up to 27m. This provides more flexibility when fitting the boilers, as it removes the need to flue them concentrically through the closest external wall or roof.

For more information about how a Keston twin flue boiler can make challenging installations easier, head to our page Why Keston?, or discover our in-depth case studies on the Keston news hub.